DTF print technology transforms creative production, offering precision, efficiency, and sustainability for apparel designers and manufacturers. Its direct transfer method eliminates setup, speeds up production, maintains design vibrancy, and handles diverse materials while minimizing waste and resource use, making it an eco-friendly game-changer.

“Discover how DTF (Direct to Fabric) print technology is transforming the printing industry. This innovative process offers a myriad of advantages, from unlocking boundless creative possibilities for designers to enhancing efficiency and precision in production.

In this article, we explore why DTF Print Advantages are set to redefine the future of printing. We delve into its impact on sustainability, offering eco-friendly solutions that benefit both businesses and the environment. Prepare to be captivated by the revolutionizing potential of DTF printing.”

- Unlocking Creative Possibilities: DTF Print Revolution

- Efficiency and Precision: Advantages Over Traditional Methods

- Sustainable Future: Eco-Friendly DTF Printing Solutions

Unlocking Creative Possibilities: DTF Print Revolution

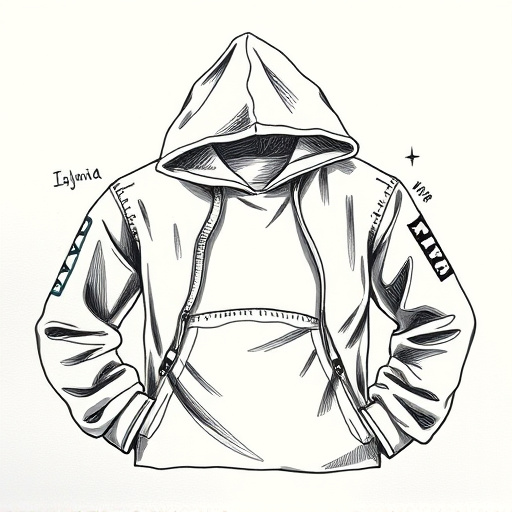

DTF print technology is unlocking a world of creative possibilities for designers and manufacturers alike. This revolutionary process offers a unique approach to printing on various materials, especially in the apparel industry. With DTF for apparel, designers can bring their most intricate and detailed visions to life with stunning accuracy. It’s not just about aesthetics; DTF printing for t-shirts and other fabrics provides a durable and high-quality finish, ensuring that designs maintain their vibrancy even after multiple washes.

The versatility of DTF print advantages is evident in its ability to handle complex designs and shapes seamlessly. Unlike traditional methods, cold peel DTF transfers allow for precise placement and intricate details, making it an ideal solution for creating unique, personalized, and trendy garments. This technology empowers brands and artists to stay ahead of the curve, offering them a competitive edge in the ever-evolving fashion landscape.

Efficiency and Precision: Advantages Over Traditional Methods

Direct to film (DTF) print technology offers significant advantages over traditional printing methods when it comes to efficiency and precision. With DTF, designs are transferred directly onto the surface of custom sheets for heat pressing designs onto garments, eliminating the need for complex setup processes typically required in screen printing or digital printing. This streamlined approach results in faster production times, making it an ideal solution for on-demand printing and small to medium batch sizes.

Moreover, DTF print advantages extend to enhanced precision and detail retention. The technology allows for high-resolution printing directly onto the heat transfer paper, ensuring that intricate patterns and fine lines are accurately reproduced on the final product, such as direct to film personalized hoodies. Unlike traditional methods, which might struggle with detailed designs or experience color bleeding, DTF print delivers vibrant and precise results, making it a preferred choice for creating custom garments and other printed materials that demand exceptional quality.

Sustainable Future: Eco-Friendly DTF Printing Solutions

The future of printing is sustainable and eco-friendly, with Digital Thermal Transfer (DTF) print advantages taking center stage. This innovative technology offers a greener alternative to traditional printing methods, addressing environmental concerns that have long plagued the industry. DTF printing minimizes waste by using digital imaging to transfer designs directly onto various materials, reducing the need for chemical inks and excessive water consumption.

With a focus on sustainability, DTF print advantages include the ability to print on demand, eliminating overproduction and minimizing the carbon footprint associated with storing excess inventory. Moreover, the process uses less energy compared to heat presses, making it an environmentally conscious choice. The best DTF printer models are designed to handle a wide range of materials, including cotton, polyester, and even plastic, allowing for versatility in production while ensuring that each step of the printing process is kind to the planet.

DTF print technology offers a compelling mix of creativity, efficiency, and sustainability that positions it as the future of printing. By unlocking new creative possibilities, providing precise results, and minimizing environmental impact, DTF print advantages are undeniable. As we move forward, embracing this innovative approach will not only benefit businesses but also contribute to a greener world.