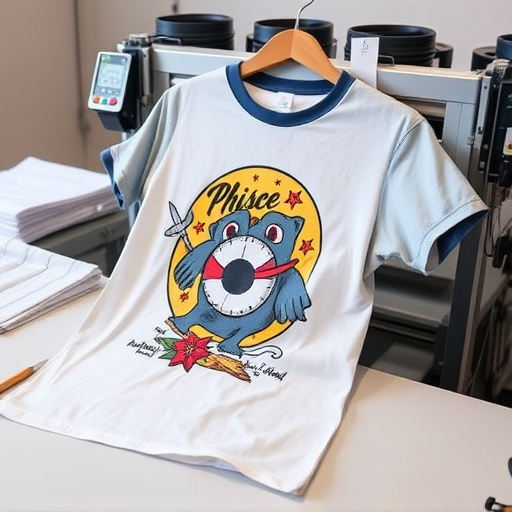

DTF Print (Direct to Film) technology offers unparalleled versatility in printing, enabling exploration of various materials and surfaces. Cost-effective for small to medium runs, it streamlines production, reduces waste, and cuts turnaround times. Its precision allows intricate designs with long-lasting durability on diverse fabric types, making it a game-changer for apparel customization while embracing greener practices.

“Discover how DTF (Direct to Fabric) Print is revolutionizing the printing industry, offering a dynamic blend of creativity, efficiency, and sustainability. This cutting-edge technology is unlocking new possibilities for designers and businesses alike. From its versatility in creating stunning, custom designs on various fabrics to its eco-friendly approach, DTF Print is set to redefine quality and precision in the world of printing. Explore the benefits and understand why DTF Print advantages are shaping the future of the industry.”

- Unlocking Creative Potential: DTF Print's Versatility

- Efficient and Eco-Friendly: The Green Revolution in Printing

- Redefining Quality: Precision and Detail in DTF Print

Unlocking Creative Potential: DTF Print's Versatility

DTF Print (Direct to Film) technology is unlocking a new realm of creative potential in the printing industry. One of its key advantages lies in its versatility, allowing designers and printers to experiment with various materials and surfaces. Whether it’s bright, vibrant colors on light fabrics or subtle, nuanced designs on dark garments, DTF Print offers unparalleled flexibility. This method directly prints onto film, eliminating the need for expensive plates, making it an efficient choice for small to medium-sized runs and custom orders.

For those seeking the best DTF printer for their business, the technology’s adaptability is a significant selling point. It can be used on a wide range of items, from apparel and accessories to signage and promotional products, ensuring that businesses can cater to diverse customer demands. The direct to film printer streamlines production processes, reduces waste, and enables faster turnaround times, making it an attractive option for modern printing enterprises.

Efficient and Eco-Friendly: The Green Revolution in Printing

The printing industry has undergone a significant transformation with the advent of Direct-To-Fabric (DTF) print technology, leading to a greener and more efficient future. Traditional printing methods often relied on toxic chemicals and substantial waste generation, contributing to environmental concerns. However, DTF offers a sustainable solution by eliminating many of these issues. This process directly applies designs to fabric using advanced heat transfer techniques, reducing the need for intermediate materials and minimizing chemical exposure.

As a result, DTF print advantages extend beyond efficiency; it is also an eco-friendly approach. By streamlining the production process and using specialized dtf heat transfer paper, waste reduction is significant. This method allows for precise and detailed printing, ensuring minimal material waste during production. With its ability to cater to various fabric types and colors, DTF is particularly advantageous in industries like apparel manufacturing, where rapid design customization and sustainable practices are increasingly demanded by consumers.

Redefining Quality: Precision and Detail in DTF Print

DTF Print redefines quality by offering unprecedented precision and detail in each print. Unlike traditional methods that might struggle with intricate designs or fine lines, DTF excels at producing sharp, crisp images even on the smallest scales. This advantage is particularly noticeable when creating personalized items like direct to film hoodies, where every element must be accurately represented. The technology ensures that textures, gradients, and subtle details are rendered flawlessly, elevating the overall aesthetic appeal of the final product.

Moreover, DTF Print’s precision translates into enhanced durability for garments, especially when used with light fabrics. The cold peel dtf transfers, which are meticulously applied using advanced machinery, adhere strongly to the fabric while preserving its breathability and comfort. This not only guarantees longer-lasting designs but also allows for a wider range of creative possibilities in clothing customization, making DTF Print a game-changer in the printing industry.

DTF print technology offers a compelling mix of creative versatility, environmental sustainability, and superior quality, making it a clear choice for the future of printing. By leveraging these advantages, businesses can unlock new levels of innovation, reduce their ecological footprint, and deliver products that captivate customers. As we move forward, embracing DTF print’s capabilities will not only drive progress but also ensure a more sustainable and vibrant future for the industry.