DTF (Direct to Fabric) print technology has revolutionized product design, especially in clothing and textiles, by offering high-quality, precise printing directly onto diverse fabrics. Its key advantages include versatility for intricate designs on various fabric types, fast drying times and superior durability via heat press, and on-demand production for promptly catering to individual customer preferences. DTF printing's benefits make it an attractive option for businesses seeking efficiency, cost-effectiveness, and customization, as highlighted in numerous case studies. Its applications range from personalized hoodies with intricate logos in apparel to rapid prototyping, demonstrating its integral role in modern product design.

“Discover how DTF (Direct to Forme) print technology is revolutionizing product design. This article explores the untapped potential of DTF print advantages, offering a precise and efficient method for rapid prototyping and low-volume production. We delve into how this innovative process enhances design flexibility, material choices, and product customization. Through case studies, we showcase successful implementations, demonstrating the transformative impact of DTF printing on various industries. Uncover why embracing DTF print advantages is a game-changer for modern product design.”

- Understanding DTF Print Technology and Its Benefits

- Enhancing Product Design with DTF Print Advantages

- Case Studies: Successful Implementations of DTF Printing in Product Design

Understanding DTF Print Technology and Its Benefits

DTF (Direct to Fabric) print technology has revolutionized product design, especially in clothing and textile industries. This innovative process allows for high-quality, precise printing directly onto various fabrics, offering numerous advantages over traditional methods. By eliminating the need for intermediate materials and complex setups, DTF printing streamlines production, making it an attractive option for businesses seeking efficiency and cost-effectiveness.

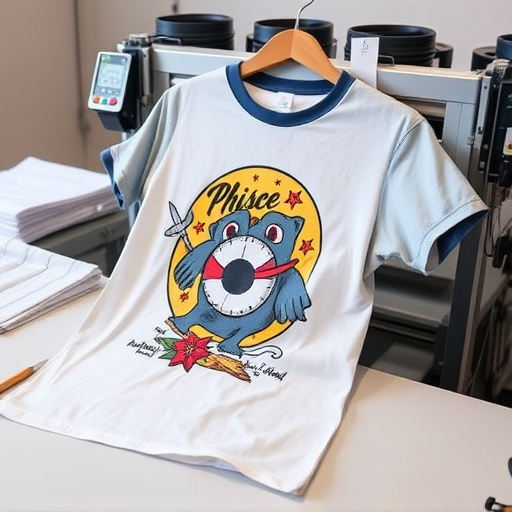

One of the key DTF print advantages is its versatility. It enables designers to create intricate, detailed designs with vibrant colors on a wide range of fabric types, from cotton t-shirts to polyester sweatshirts. The heat press technology used in DTF printing ensures fast drying times and superior durability, making it ideal for heat press applications like custom t-shirt printing. Moreover, this technology allows for on-demand production, enabling businesses to cater to individual customer preferences and demands promptly.

Enhancing Product Design with DTF Print Advantages

Incorporating DTF (Direct to Film) print technology into product design offers a myriad of advantages that revolutionize the way we approach customization and innovation. This cutting-edge method allows for the creation of direct, high-quality prints on various materials, including fabrics like personalized hoodies. By eliminating the need for intricate and time-consuming processes, DTF printing streamlines production while ensuring exceptional results. The technology’s versatility is a game-changer; it enables designers to bring unique, visually appealing, and highly personalized products to market swiftly.

DTF print advantages extend beyond speed and efficiency. It offers an unparalleled level of detail and color accuracy, making it ideal for intricate designs and complex artwork. This precision results in superior product quality, ensuring that each piece meets high standards. Moreover, DTF printing allows for cost-effectiveness, especially when producing small batches or one-of-a-kind items, as it minimizes waste and optimizes material usage, making it a preferred choice for forward-thinking brands and designers.

Case Studies: Successful Implementations of DTF Printing in Product Design

Direct To Film (DTF) printing has revolutionized product design, offering a host of advantages that have been successfully leveraged in various case studies. One notable application is in the customization of apparel, such as personalized hoodies with intricate direct-to-film logos. This method allows clothing brands to achieve high-quality, detailed designs on demand, enabling them to meet diverse customer preferences and personalize products at scale.

Another example demonstrates DTF Print Advantages in rapid prototyping. Designers can swiftly bring concepts to life by printing directly onto various materials, including fabrics, plastics, and metals. This efficiency streamlines the design process, allowing for quicker market entry and the ability to iterate on designs based on real-world feedback. These successful implementations highlight how DTF printers, with their versatility and precision, are integral tools in modern product design, catering to both custom apparel needs and rapid prototyping demands.

DTF (Direct to Forme) print technology offers significant advantages in product design, allowing for precise customization, faster production times, and enhanced aesthetic appeal. By leveraging these benefits, designers can create innovative products with unique structural features and intricate details. The case studies presented demonstrate the successful integration of DTF printing into various industries, highlighting its potential to revolutionize product development and meet the evolving demands of modern markets. Embracing DTF Print Advantages empowers designers to push boundaries, achieve complex designs, and deliver exceptional products that captivate consumers.