DTF (Direct to Film) print tech offers precision, vibrant colors, and intricate details for high-quality custom designs on various materials. It empowers businesses to create unique transfers for apparel, enhancing creative expression in fashion. To maximize DTF advantages, prepare high-res vector graphics, use templates for positioning, match color modes, and pre-test prints for optimal outcomes.

Unleash the power of Direct-to-Fabric (DTF) printing and elevate your design game! This article guides you through mastering the art of DTF print, offering a unique advantage in the world of textile customization. Discover how this technology revolutionizes creating vibrant, high-quality prints on a variety of fabrics. From understanding its benefits to preparing designs and achieving crisp results, we’ll explore essential tips for maximizing your DTF printing experience.

- Understanding DTF Print Technology and Its Benefits

- Preparing Your Designs for Optimal DTF Printing

- Achieving Crisp Quality: Tips for Best Results

Understanding DTF Print Technology and Its Benefits

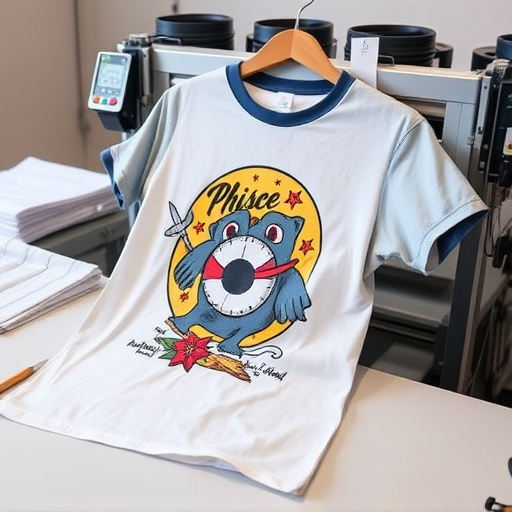

DTF (Direct to Film) print technology is revolutionizing the way we create custom designs on a variety of materials, from t-shirts and hoodies to mugs and more. It offers several advantages over traditional printing methods. One of its key benefits is precision; DTF can reproduce intricate details and vibrant colors with remarkable accuracy, making it ideal for high-quality, personalized items. This technology directly applies ink to the surface of the film, ensuring a smooth and even finish that enhances the final product’s aesthetic appeal.

Additionally, DTF printing allows for a wide range of design possibilities, including direct application on various fabrics and materials without the need for intermediate transfers. It is particularly advantageous for creating custom dtf transfers, enabling businesses to offer personalized hoodies and apparel with direct to film techniques. This level of customization not only caters to individual preferences but also opens up new opportunities for creative expression in the fashion industry.

Preparing Your Designs for Optimal DTF Printing

To make the most of DTF (Direct-to-Fabric) printing’s advantages, preparing your designs with specific considerations in mind is paramount. Start by ensuring your design files are at the correct resolution—high enough to maintain detail but not excessively large, which can hinder printing speed and quality. Vector graphics are generally preferred as they scale smoothly without losing quality. For bulk DTF shirt production, consider using templates or layout software to precisely position your designs on the fabric, especially when creating custom DTF transfers for dark fabrics. This process allows for precise alignment and minimizes errors.

Additionally, understanding color profiles is crucial. Different printing methods interpret colors differently, so ensuring your design’s color mode matches the printer’s capabilities is essential. For DTF printing, CMYK color mode is typically used. Correctly preparing your designs with these factors in mind will not only enhance the final print quality but also streamline the production process, offering a superior DTF printing experience and exceptional results.

Achieving Crisp Quality: Tips for Best Results

Achieving Crisp Quality: Tips for Best Results

One of the key DTF print advantages is its ability to produce sharp, vibrant designs on a variety of fabrics. To ensure top-notch results when using direct-to-fabric (DTF) printing techniques, especially for items like hoodies and t-shirts, there are several best practices to keep in mind. First, invest in high-quality DTF printers designed for precise, detailed prints. Using top-tier equipment ensures that your designs are accurately replicated on the fabric.

Additionally, prepare your design files properly before printing. Ensure that images are at a high resolution (300 DPI or better) and that text is clear and sharp. The right software settings can also make a significant difference; calibrate your DTF printer according to the manufacturer’s guidelines for optimal color accuracy. Lastly, pre-test prints on scrap fabric to adjust settings as needed before applying the design to your final product, whether it’s a hoodie or a t-shirt.

Applying DTF (Direct to Fabric) print technology offers a multitude of advantages, from vibrant colors and crisp details to versatile material options. By understanding the benefits and following best practices for design preparation and printing techniques, you can harness the full potential of DTF Print advantages, ensuring exceptional results that enhance your creative projects.