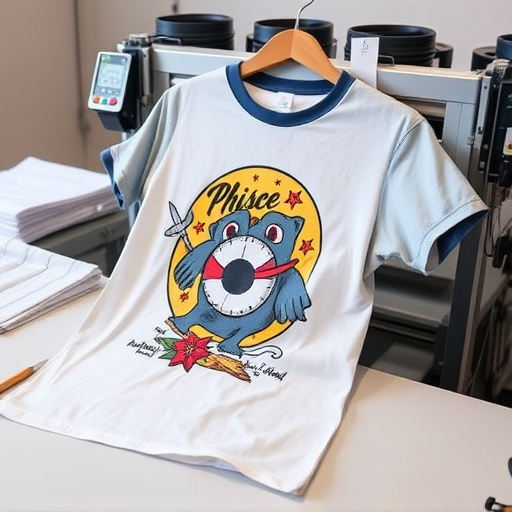

DTF printing offers significant advantages for customization and production in small to medium batches, eliminating traditional printing methods to directly apply designs onto fabrics like cotton, polyester, and blends. It allows businesses to create unique, customized products with vibrant colors using DTF heat transfer paper. Strategic material choices, including high-performance inks and top-tier transfer films, ensure lasting prints on dark fabrics. DTF technology streamlines production, reduces waste, maintains detail, and offers cost savings compared to traditional methods for printing light fabrics like t-shirts.

“Unleash the potential of Direct to Fabric (DTF) printing and discover the key elements that ensure its success. This comprehensive guide explores the intricate world of DTF printing, offering valuable insights for businesses seeking a competitive edge. From understanding the technology’s fundamentals to optimizing print quality and efficiency, we uncover essential practices. Learn how to enhance durability, maximize cost savings, and create vibrant, long-lasting designs on fabric. Embrace the DTF Print Advantage and revolutionize your textile production.”

- Understanding Direct to Fabric (DTF) Printing

- Essential Elements for Print Quality and Durability

- Maximizing Efficiency and Cost Savings in DTF Printing

Understanding Direct to Fabric (DTF) Printing

Direct to Fabric (DTF) Printing is a cutting-edge technology that has revolutionized the way we create and personalize garments. It’s more than just a printing method; it offers a unique set of DTF Print Advantages for businesses and designers. This process involves printing designs directly onto fabric using specialized equipment, eliminating the need for intermediate steps like screens or plates. As a result, it becomes an efficient and cost-effective solution for small to medium-scale production runs, making it ideal for custom apparel, promotional items, and on-demand printing.

One of the key benefits is its versatility, especially when it comes to DTF printing for light fabrics. Different fabric types, including cotton, polyester, and blends, can be printed upon directly, ensuring vibrant and long-lasting colors. The use of DTF heat transfer paper further enhances this process by allowing for precise control over design placement and enabling the application of complex artwork on various products like hoodies, t-shirts, and more. This technology has truly brought personalization to a whole new level, fostering creativity and enabling businesses to offer unique, customized items with remarkable ease.

Essential Elements for Print Quality and Durability

Achieving exceptional print quality and durability is a cornerstone of any successful DTF (Direct to Fabric) print advantage strategy. The key lies in selecting the right materials and adhering to precise techniques. For optimal results on dark fabrics, such as those used in hoodies, professionals recommend using high-quality dtf printing inks specifically designed to penetrate and adhere to darker surfaces effectively. This ensures vibrant colors that stand out even after repeated washes.

Additionally, investing in top-grade dtf transfer film plays a crucial role in achieving long-lasting prints. The right film should offer precise detail reproduction, smooth texture, and excellent heat resistance during the printing process. By combining these essential elements—the right inks and transfer films—printers can deliver not only visually stunning designs but also ensure the longevity of their work, catering to customers who demand high-quality, long-lasting dtf printing for hoodies and other fabric items.

Maximizing Efficiency and Cost Savings in DTF Printing

In the realm of DTF Print Advantages, maximizing efficiency and cost savings are paramount. A direct to film (DTF) printer facilitates a streamlined printing process for light fabrics, such as t-shirts, by eliminating intermediate steps like plate making or screen preparation. This not only accelerates production time but also reduces waste, as the printer precisely applies ink directly onto the fabric, ensuring every detail is crisp and vibrant.

The efficiency gains of DTF printing are further amplified by its ability to handle a variety of design complexities and material types without compromising quality. Whether it’s intricate graphics or bold colors, DTF printers excel in delivering consistent results. Additionally, the cost-effectiveness stems from lower operational expenses compared to traditional printing methods, making it an attractive option for businesses aiming to optimize their production costs while maintaining high-quality DTF print advantages on light fabrics like t-shirts.

Direct to fabric (DTF) printing offers a unique set of advantages, from superior print quality and durability to significant cost savings and efficiency gains. By understanding the key elements discussed in this article, businesses can harness the full potential of DTF technology, ensuring vibrant, long-lasting prints that enhance their marketing efforts and satisfy customers alike. Leverage these insights to stay ahead in the competitive landscape of custom apparel and product printing.